Robotics integration is changing the way businesses operate. With the help of robots, tasks that used to take hours can now be done quickly and accurately. This technology is helping companies improve efficiency, reduce errors, and save money.

From manufacturing to customer service, robotics is being used in many areas to streamline work processes. In this article, we’ll explore how robots are transforming business workflows and what it means for the future of work.

Boosting Efficiency With Robotic Automation

Robotic automation is a great way to boost efficiency in business. Robots can work quickly and accurately, completing tasks much faster than humans. They don’t need breaks, so they can keep working around the clock.

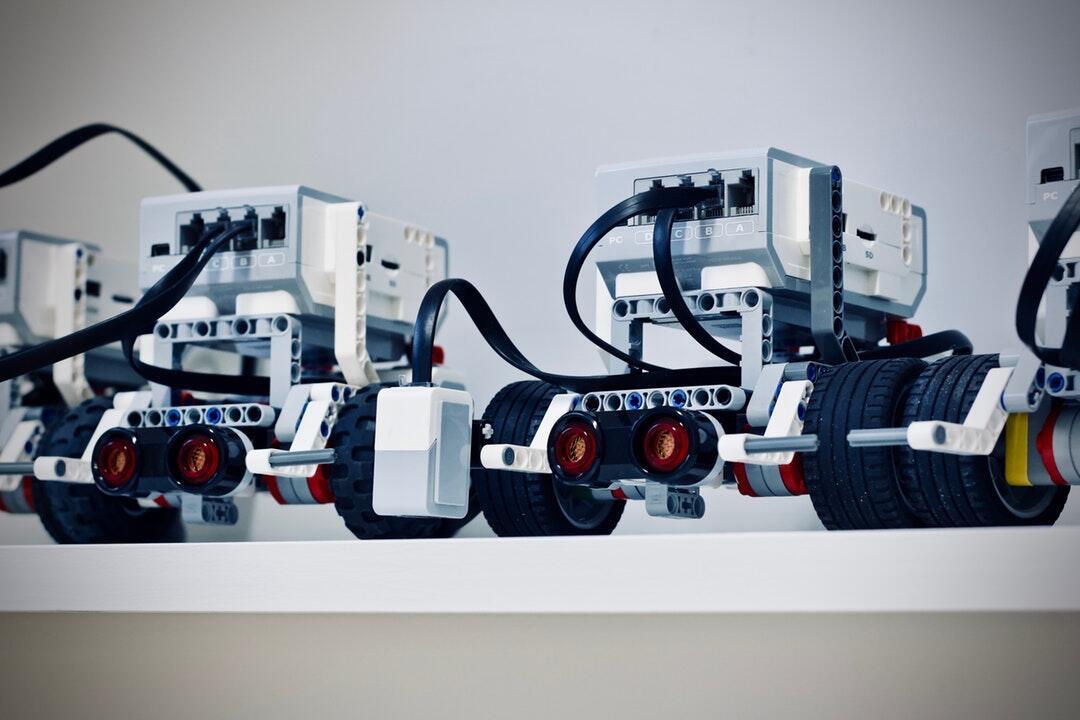

This helps companies get more done in less time. Robots are also able to repeat tasks without making mistakes, which reduces errors. For example, FTC Robots are designed for precision and speed. Businesses can use robots to handle repetitive jobs.

This allows employees to focus on more complex and creative work. In the end, robotic automation helps businesses save time, increase output, and improve overall efficiency.

Reducing Errors and Improving Accuracy With Robotics

Robotics can greatly reduce errors and improve accuracy in business tasks. Unlike humans, robots don’t get tired or distracted, so they can do the same task repeatedly without mistakes. They are programmed to follow exact instructions, which ensures precision in their work.

In industries like manufacturing, robots can assemble products with exact measurements, reducing the chances of defects. Robots can also handle data entry and calculations without errors, which helps businesses stay organized.

With robotics, there is less need for rework or corrections, saving time and money. The consistent performance of robots helps improve the quality of products and services. As a result, businesses can offer better products to their customers and maintain a strong reputation.

Cost Savings

Robotics can help businesses save a lot of money. Since robots work quickly and don’t need breaks, they can do more work in less time. This means businesses can reduce labor costs and increase production.

Robots also reduce errors, which cuts down on costly mistakes or rework. With robots handling repetitive tasks, businesses can reassign workers to more important jobs. Over time, using robots can lower overall operating costs.

They are also more energy-efficient than many machines, saving money on power bills. In the long run, investing in robotics can lead to big savings for a business.

Transforming Manufacturing With Robotic Integration

Robotic integration is changing the way manufacturing works. Robots are now used to assemble products, handle materials, and even package items. They can work faster and more accurately than humans, making production lines much more efficient.

Robots also reduce the risk of accidents by taking on dangerous tasks, which keeps workers safe. With robotic systems, manufacturers can produce more goods in less time and at a lower cost.

Robots can also help create products with high precision, improving the overall quality. In the long run, robotic integration in manufacturing helps companies stay competitive and meet customer demands. This transformation is making the industry more modern and productive.

Enhancing Customer Service Through Robotic Assistance

Robotic assistance is improving customer service in many businesses. Robots can quickly respond to customer questions, both online and in stores. They are available 24/7, which means customers can get help anytime they need it.

Robots can handle simple tasks, like answering common questions or guiding customers through processes. This allows human workers to focus on more complex issues.

For example, chatbots can assist customers on websites, helping them find products or solve problems without waiting. Robots can also be used in stores to guide customers or check inventory. By using robotics, businesses can offer faster, more efficient customer service, improving the overall customer experience.

Increasing Flexibility in Business Operations With Robotics

Robotics can greatly increase flexibility in business operations. Robots can be easily reprogrammed or adjusted to handle different tasks, allowing businesses to adapt to changing needs.

For example, if a company needs to switch production lines or add new products, robots can quickly be set up for those tasks. This makes it easier for businesses to respond to new market demands or unexpected challenges.

Robots can also work in various environments, from warehouses to manufacturing floors, without requiring major changes. Their ability to take on different roles allows businesses to use their resources more effectively.

With robotics, companies can scale operations up or down quickly, helping them stay competitive and efficient. In the long run, this flexibility helps businesses keep up with growth and stay agile in a fast-changing market.

Improved Consistency and Quality Control

Robotics help improve consistency and quality control in business. Robots follow exact instructions every time, which reduces the chance of mistakes. This means products are made with the same high quality each time.

In manufacturing, robots can assemble items with precision, ensuring that everything fits perfectly. They can also check products for defects and remove any that don’t meet quality standards.

Unlike humans, robots don’t get tired or distracted, so their performance stays steady throughout the day. This helps businesses deliver better products to customers and maintain a strong reputation. With robotics, companies can ensure their products are reliable and meet the highest standards.

Reduced Labor Strain and Health Risks

Robotics can help reduce labor strain and health risks for workers. Many jobs in factories or warehouses require heavy lifting or repetitive movements, which can cause injuries over time.

Robots can take over these physically demanding tasks, allowing workers to focus on less stressful duties. This reduces the risk of injuries like back pain or muscle strain. By using robots for tasks like lifting, carrying, or assembling, businesses can protect their employees’ health.

Workers are less likely to suffer from fatigue or repetitive stress injuries. This leads to a safer work environment and helps keep employees happy and healthy. Using robots for tough jobs can also improve overall workplace productivity.

Learn All About Robotics Integration

Robotics integration is transforming how businesses operate by improving efficiency, reducing errors, and cutting costs. Robots help companies produce more, work faster, and ensure higher quality.

They also make businesses more flexible, safe, and able to meet customer needs quickly. As technology advances, robotics will continue to play a key role in shaping the future of work. Embracing this technology can lead to significant benefits and a more productive business environment.

Visit our blog for more!